PUMPSENSE FLUID ENGINEERING PVT LTD

PUMPSENSE FLUID ENGINEERING PVT LTD

|

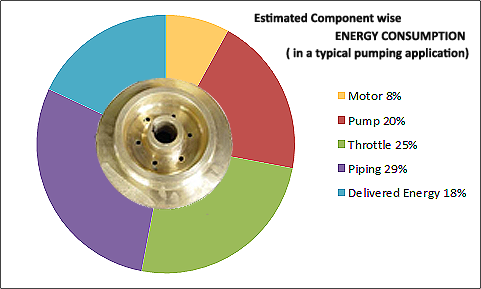

An estimated 30% of the total electrical energy consumption by the industrial sector is used to drive pumps. The share of pumps in the electricity consumption within specific industries ranges from 20% to 60%. Clearly, the efficiency of pumps is a critical factor in energy conservation and the reduction of carbon emission. The pump is often the most inefficient of the components that comprise a pumping system including motor, transmission, drive, piping and valves. It has been estimated that 85% of the lifecycle cost of a pump can be attributed to the energy costs and a mere 1% improvement in efficiency has a pay off equal to the cost of the pump. |

|

Deficiency in pump specification is often a major reason for sub-optimal pump performance.These deficiencies relate to inacurate specification of rated flow, head, maximum/minimum flow requirement, range of operation etc. Specification deficiencies affect safety, reliability, operational costs, maintainence costs, capital costsand hydraulic performance.

|

PUMPSENSE WILL PROVIDE CUSTOM DESIGNED IMPELLER TO OPTIMISE PERFORMANCE OF EXISTING PUMPS |

|||||||||||||

When a standard impeller does not offer an optimal solution in in terms of

PUMPSENSE can provide a Impeller Design. This design will be :

|