PUMPSENSE FLUID ENGINEERING PVT LTD

PUMPSENSE FLUID ENGINEERING PVT LTDPUMP |

QUIZ |

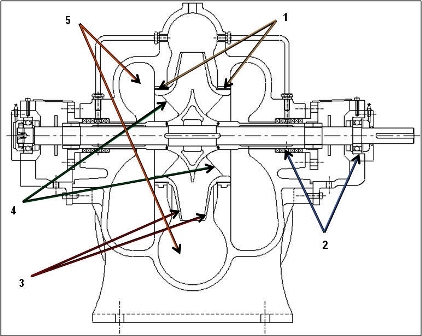

| Qs01 | The following figure shows various types of losses in a centrifugal pump. Please identify the labels with their positions & select the right option-

|

Answers |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

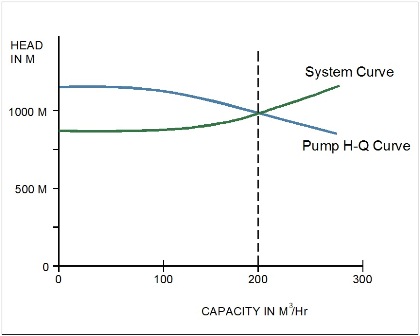

| Qs02 | Pump H-Q curve has been

superimposed on the system curve in the figure below. Identify

the head figures.

|

Answers |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

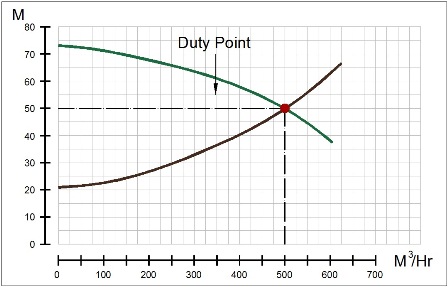

| Qs03 | The figure below represents curves for a pumping system. One would expect a system curve of this nature in the following systems.

|

Answers | i) A ii) B iii) C iv) D |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Qs04 | If the system head is over estimated or if multiple margins are added to arrive at the pump total head, the pump performance will be sub-optimal. Which of the following statement is not true for such a system?

|

Answers |

i) Pump will discharge more than rated

discharge ii) Motor may get overloaded iii) NPSHa may not be sufficient to supress cavitation iv) Axial thrust will increase v) Radial thrust will increase |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Qs05 | When the required discharge of a pump is less than the normal discharge (valve fully open) and pump runs at a constant speed, throttling in the discharge line is sometimes adopted to reduce the flow. Throttling is an energy inefficient method of flow control but can be used with pumps using radial flow impellers. What is the main reason why throttling is not recommended for pumps with mixed flow or axial flow impellers: A. Excessive radial thrust load at part

capacity |

Answers | A B C D E | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Qs06 | The figure represents two identical pumps working in parallel in a water supply system. Water level in the suction sump varies between high & low limits. Please identify the labels in the diagram & put a tick mark against there right match:

|

Answers |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Qs07 | Air entrainment in the suction side of the pump can affect pump performance in diverse ways. Which of the following statements about air entrainment is not true for centrifugal pumps? A. Even with

small amounts of air in the liquid the performance of the pump

declines |

Answers | A B C D E | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Qs08 | The following is mixed-up list of

advantages of split case (SC) and end suction (ES) pumps. Each

option contains some item nos. under the boxes, please select

the right option that correctly segregates the advantages for

both the pump types:

|

Answers |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Qs09 | You have a double volute axially split case pump 14"x16" in size used for cold well duty of 5000 Igpm (1362 m3/hr.) and 150 ft (45.7 m) at 980 rpm. NPSH required by the pump at 980 rpm is 3.3 m and power absorbed is 200 kW (pump eff. 85%). You want to run the pump at 1480 rpm for a different application and the pump manufacturer has confirmed that the design speed of this pump is 1500 rpm. Please estimate the performance of the pump at 1480 rpm.

|

Answers | i) A ii) B iii) C iv) None |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Qs10 | Following are the typical cost items in a life cycle cost (LCC) analysis of a pumping system. Approximate % costs are presented as a separate list. Please try to match the cost items with your best estimate of percentage figures:

|

Answers |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||