|

| |

|

| |

| Pump Pattern |

|

| The core of the suction volute in the upper case of the split case pump. The gap between the two parts of the core form the splitter or anti-swirl vane. |

|

| |

|

| |

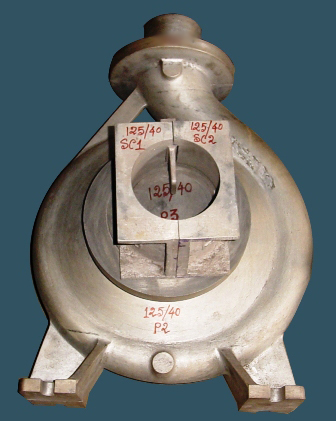

| Pump Pattern |

|

| The core of the lower half of the split case pump placed in the position in the mould box. The shapes of the suction & delivery volute cores help one to visulaise flow paths within the pumps. |

|

|

|

PATTERN MAKING |

| |

|

Fastest delivery of pump patterns in the industry

|

| |

Comprehensive QA documentation |

| |

Experience in building casing and impeller patterns for some of the largest pump makers in the USA and the UK.

|

| |

An experienced pattern inspection team |

| |

Experience in developing patterns for over three hundred split-cases, end-suction and inline pumps in the last fourteen years.

|

|

|

| TYPES OF COMPONENTS |

|

|

| Bronze Casing |

|

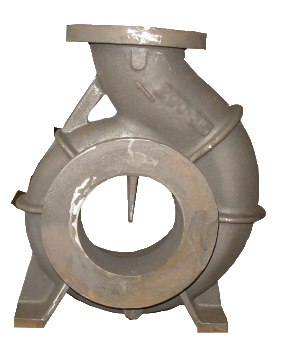

| Cast IronCasing |

|

PUMP CASING |

Axially Split Case |

| End Suction |

| Vertical Inline |

| Mixed Flow End Suction |

| Multisatge ( both Split Case & segmental ) |

| Vertical Wet- pit (diffuser / bowl ) |

| Vertical Turbine, etc |

|

PUMP IMPELLER |

Double Suction |

| Single Suction |

| Shrouded |

| Scalloped |

| Open Type |

| Radial Flow |

| Francis Vane |

| Mixed Flow |

| Axial Flow |

|

|

|

| Bronze Impeller |

|

| SS Impeller |

|

OTHER COMPONENTS |

Vertical Wet Pit Pumps- Bell Mouth |

| Delivery Bends / Motor Stool |

| End Suction & Inline Pumps - Back Covers, Power Ends / Bearing Brackets |

|

|

| FOR MORE PATTERNS AND CUSTOMISED PATTERNS......... |

|

|

| |

|

PUMPSENSE FLUID ENGINEERING PVT LTD

PUMPSENSE FLUID ENGINEERING PVT LTD  PUMPSENSE FLUID ENGINEERING PVT LTD

PUMPSENSE FLUID ENGINEERING PVT LTD